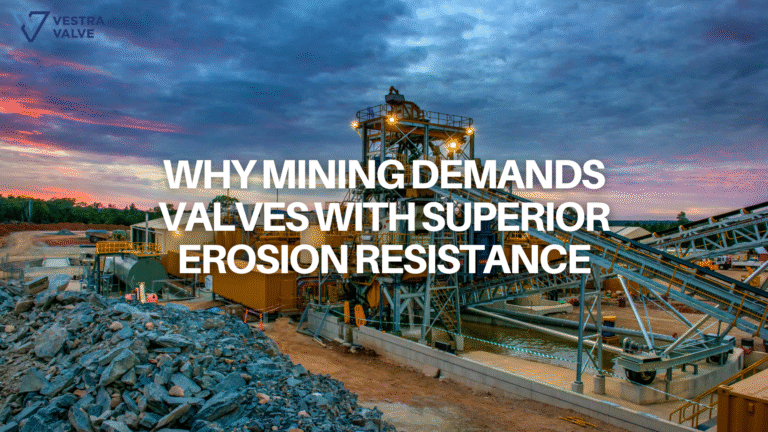

In the world of industrial operations, every detail matters, and valve leakage is one of those details that can make or break a system. Leakage in isolation valves does not simply mean that product is escaping—it means that the valve is failing. Every ounce of leakage represents lost efficiency, increased costs, and accelerated wear. More critically, a leaking valve compromises safety. In high-pressure and high-temperature operations, leakage can escalate into catastrophic failures if left unchecked.

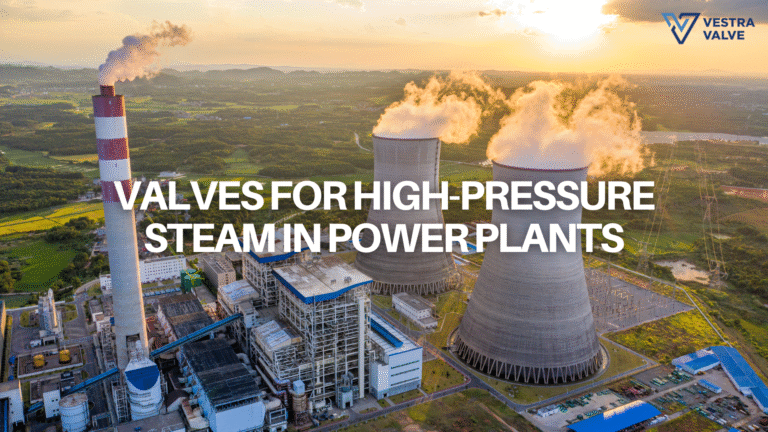

The true measure of reliability in an isolation valve is its ability to achieve zero leakage. While this has long been the standard that industries aspire to, not all valves deliver on this promise. Traditional designs struggle under extreme conditions, allowing seepage that undermines performance. For operators managing power plants, refineries, and chemical processing facilities, such compromises are unacceptable.

Vestra Valve’s commitment to zero leakage is what sets us apart. Through the use of chromium carbide coatings, precision mate-lapped seating, and pressure-assisted shutoff designs, our valves maintain perfect sealing even under stress. Combined with robust Belleville springs and blowout-proof stems, every Vestra Valve is built to shut tight and stay tight.

In a market where reliability equals profitability, zero leakage is no longer a goal—it’s a requirement. Vestra Valve doesn’t just meet that requirement, we guarantee it.