Blowout-Proof Stems & Fugitive Emissions

In critical industries, oil & gas, power generation, petrochemical, and chemical processing, valve performance is directly tied to safety and environmental responsibility. Two issues stand out as mission-critical: stem blowouts and fugitive emissions. Both can result in catastrophic accidents, regulatory penalties, and environmental harm. That’s why modern valve engineering emphasizes blowout-proof stems and advanced sealing […]

In-Line Repairability: Reducing Downtime

In today’s industrial landscape, downtime is more than just an inconvenience; it’s a direct hit to profitability, safety, and reliability. From refineries and petrochemical plants to power generation facilities, every hour a valve is offline means lost production, potential safety risks, and rising costs. That’s why in-line repairability has emerged as a game-changing innovation in […]

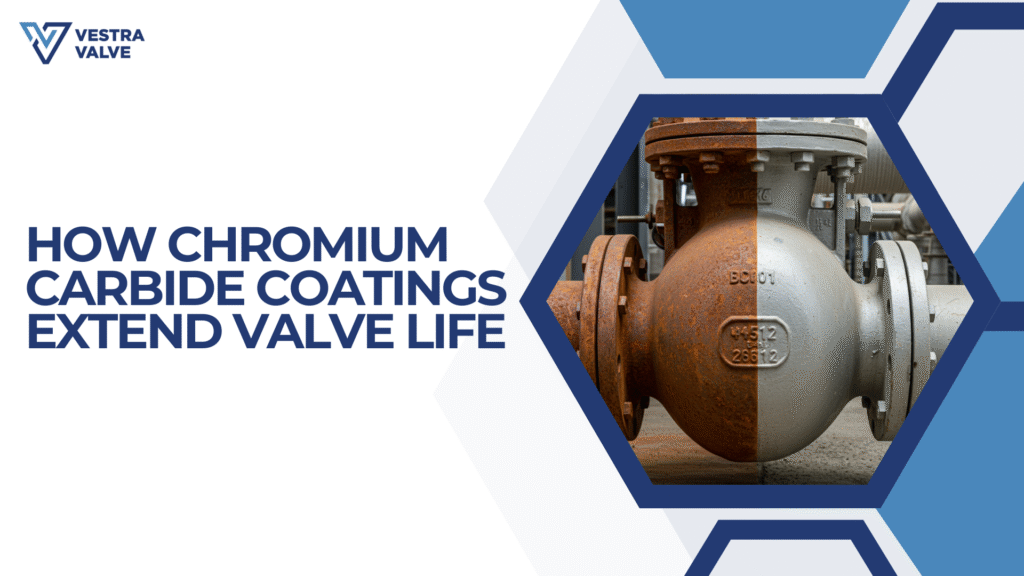

How Chromium Carbide Coatings Extend Valve Life

Valves in severe industrial service face wear, corrosion, erosion, thermal cycling, and particle impingement. These degrade sealing surfaces, trim, and internals, leading to leaks, greater maintenance, and unplanned shutdowns. Chromium carbide (e.g. Cr₃C₂‑NiCr, sometimes modified) coatings, applied via thermal spray or other advanced coating methods, can strongly extend valve component life. But to get the […]

The Science Behind Zero-Leakage Valves

In fluid control systems, leakage isn’t just an inconvenience, it’s a cost, a risk, and a threat to efficiency, safety, and compliance. Zero-leakage valves, often described as “tight shut-off” or “bubble-tight,” are engineered to prevent any measurable fluid or gas flow when closed under specific test conditions. But what does “zero-leakage” really mean? How is […]