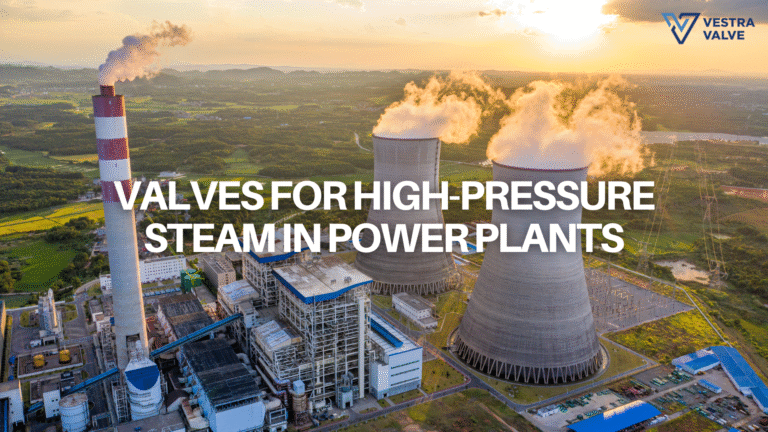

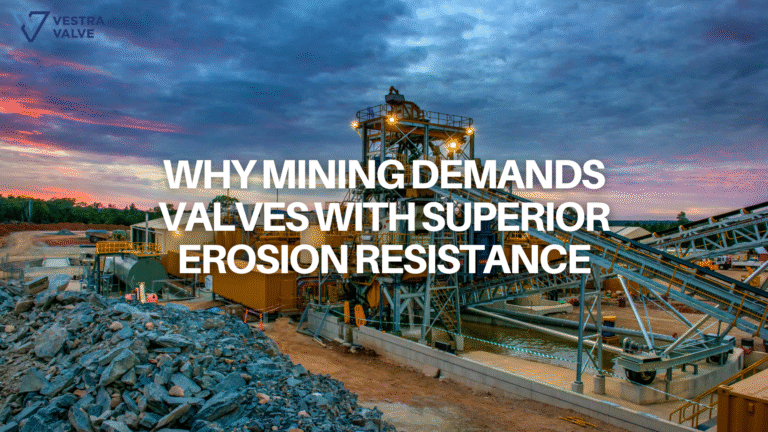

Industrial valves face some of the harshest environments on earth. From superheated steam lines in power plants to corrosive fluids in chemical facilities, valves must withstand extreme pressure and temperature while maintaining performance, safety, and reliability.

Vestra Valve’s engineering focus is clear: design valves that operate with integrity under stress, no matter the conditions.

The Challenge of Pressure & Temperature

- High Pressure: Increases the force exerted on valve components, raising the risk of leaks, deformation, or catastrophic failure.

- High Temperature: Accelerates wear, degrades seals, and weakens materials, reducing valve lifespan.

- Combined Extremes: When pressure and temperature act together, stresses multiply, making advanced design critical.

Vestra Valve’s Engineering Approach

- Metal-Seated Technology

Unlike traditional soft-seated valves, Vestra’s metal-seated ball valves retain tight shutoff at extreme temperatures where polymers fail. - Precision Machining & Materials

Valves are manufactured with robust alloys, engineered clearances, and surface finishes designed for high-stress environments. - Thermal Expansion Compensation

Vestra valves are designed to maintain sealing integrity even as components expand and contract under temperature swings. - In-Line Repairability

When exposure eventually wears components, Vestra’s split-body design allows operators to replace critical parts without removing the valve or actuator, minimizing downtime.

Safety & Reliability in Practice

In industries like refining, pulp & paper, and petrochemicals, failure isn’t an option. A leak at high temperature and pressure can compromise worker safety, equipment integrity, and environmental compliance. Vestra’s valves are built to withstand the extremes, providing operators confidence where it matters most.

The Vestra Valve Advantage

- High-performance alloys resist creep and deformation.

- Metal-seated design handles heat where others fail.

- Engineered for in-line service to reduce downtime.

When operations demand both strength under pressure and resilience under heat, Vestra Valve is engineered to deliver.