Engineering & Design

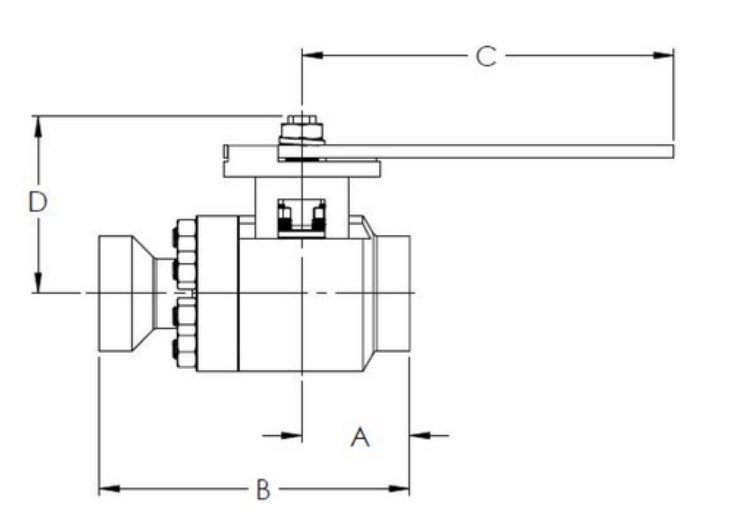

| Bore | SW End | A | B | C | D | Weight |

|---|---|---|---|---|---|---|

| 0.63 in | 3/4, 1, 1-1/2 | 2.87 in | 8.00 in | 12.00 in | 5.18 in | 22 lb |

| 1.06 in | 1-1/2, 2 | 3.47 in | 10.00 in | 12.00 in | 5.70 in | 45 lb |

| 1.50 in | 2, 2-1/2 | 4.25 in | 12.00 in | 18.00 in | 8.50 in | 85 lb |

| Bore | SW End (DN) | A | B | C | D | Weight |

| 16 mm | 20, 25, 40 | 73 mm | 203 mm | 305 mm | 132 mm | 10 kg |

| 25 mm | 45, 50 | 88 mm | 254 mm | 305 mm | 145 mm | 20 kg |

| 38 mm | 50, 65 | 108 mm | 305 mm | 457 mm | 216 mm | 39 kg |

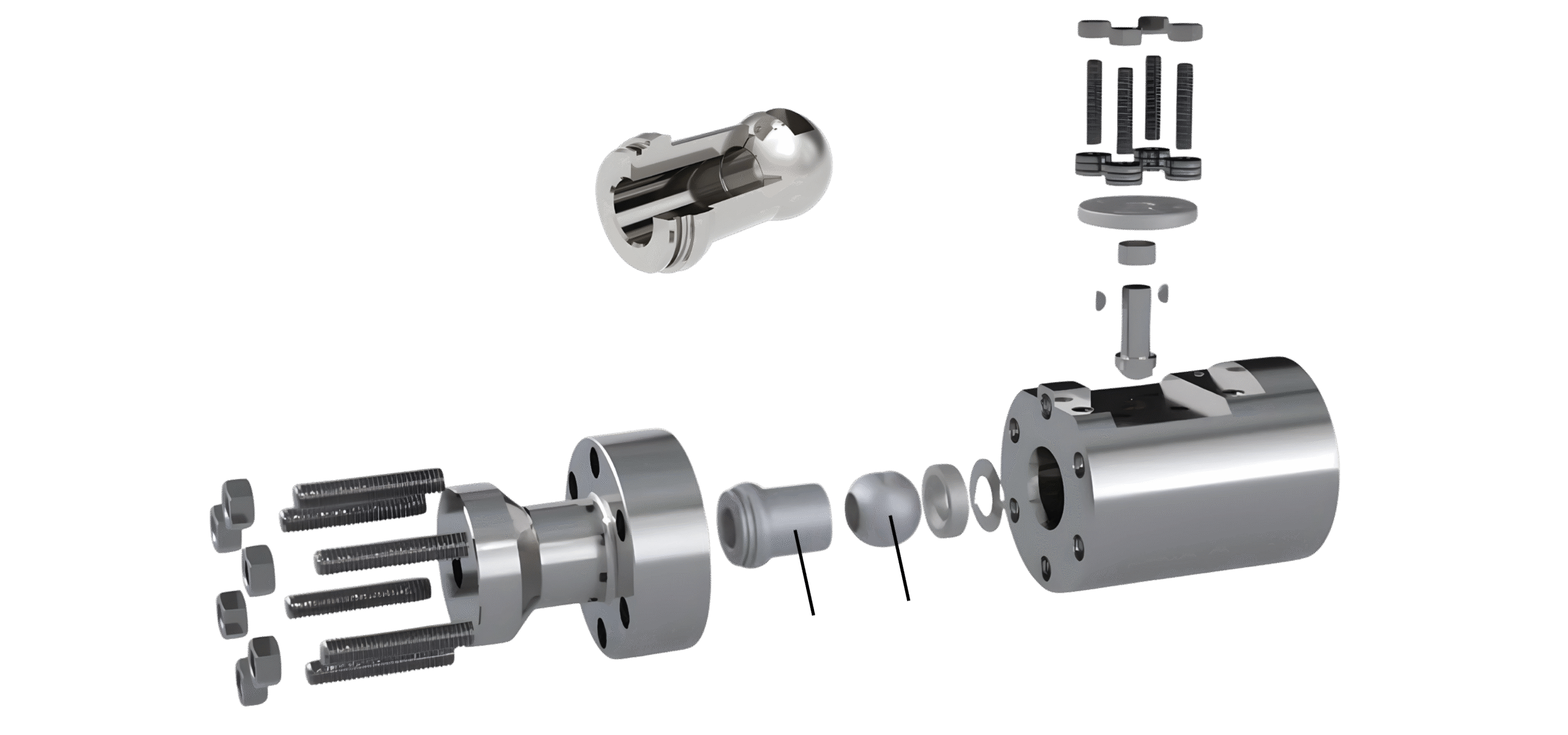

• All Vestra Valve products use rocket-applied carbide coatings, delivering industry-leading hardness and resistance to erosion, corrosion, and thermal shock.

• Vestra Valve seating surfaces maintain constant contact and are 100% protected from fluid flow erosion. Each pair of surfaces is mate-lapped-finish- machined together as one, to guarantee complete, full-contact sealing.

• Line-pressure assisted seating combined with ultra-high-strength Belleville springs ensures true zero-leakage shutoff across all pressure differentials.

• Vestra Valve’s T-shoulder blowout-proof stem (bottom-mounted) is the safest design available for this critical safety feature in high-pressure applications.

• Vestra Valve’s stem packing is live-loaded, with high-strength springs applying constant, controlled pressure. This creates a reactionary force to internal line pressure while compensating for packing volume loss due to wear, consolidation, or extrusion, ensuring a sustained, leak-tight seal and zero fugitive emissions. Additionally, the ¼-turn operation reduces packing wear and extends service life.

• Vestra Valve’s robust mounting bracket supports all actuation methods in any position. The extended bracket accommodates high-temperature insulation thicknesses common in the power industry, minimizing heat loss while protecting actuator gaskets and seals from premature failure.

• Hard stops on the mounting bracket prevent over-travel, guaranteeing precise ball-to-seat alignment in the open position.

• Vestra Valve’s split-body design allows for fast, full replacement of all critical seating components without removing actuation.